Photochemical Metal Etching

Ukusebenzisa uYilo oluNceda kwiKhompyutha (CAD)

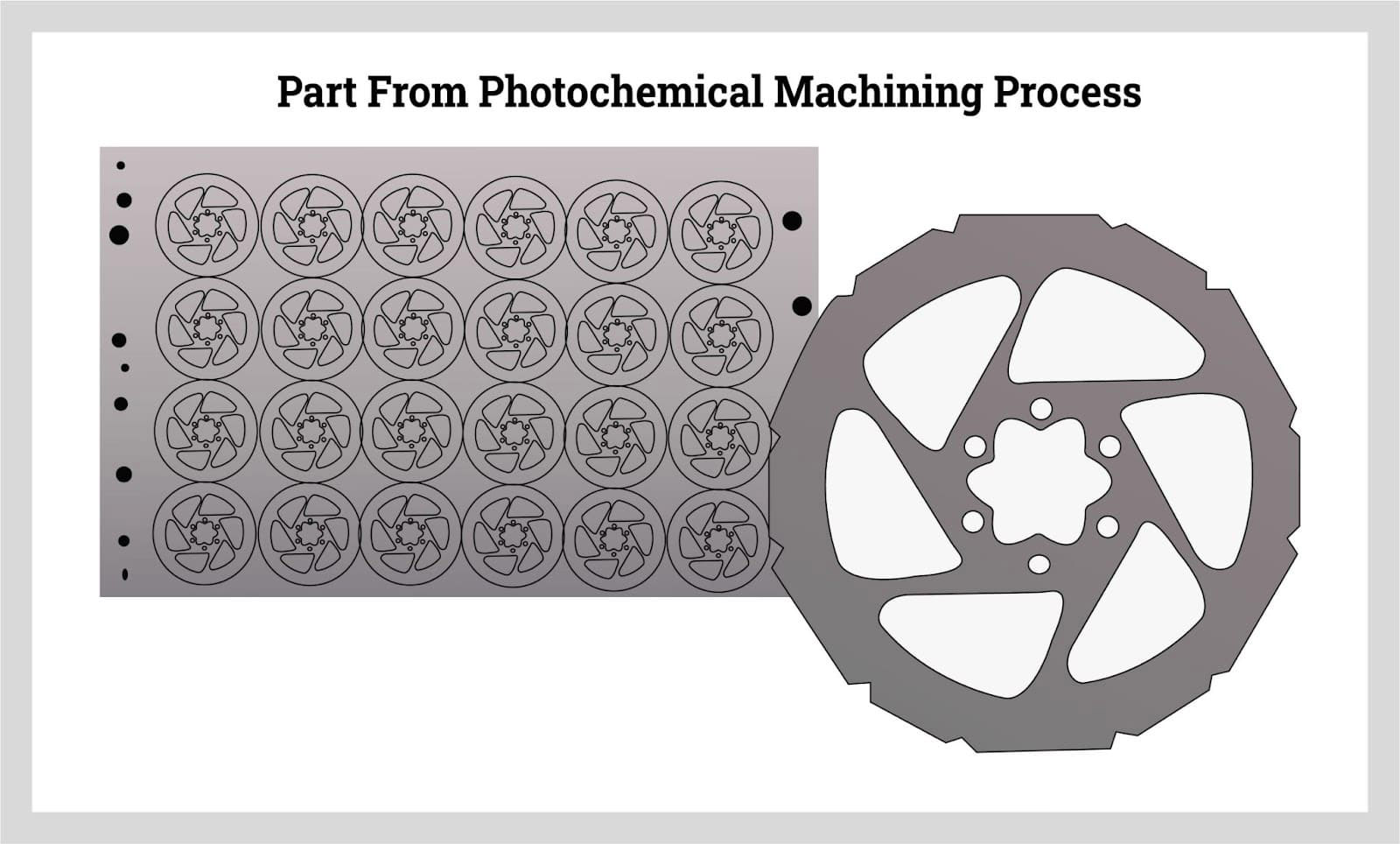

Inkqubo ye-photochemical metal etching iqala ngokudalwa koyilo usebenzisa i-CAD okanye i-Adobe Illustrator.Nangona uyilo linyathelo lokuqala kwinkqubo, ayisosiphelo sezibalo zekhompyuter.Emva kokuba unikezelo lugqityiwe, ubukhulu bentsimbi bunqunywe kunye nenani leenqununu eziya kufakwa kwiphepha, into efunekayo yokunciphisa iindleko zokuvelisa.Inkalo yesibini yobunzima bephepha kukumiselwa kokunyamezela inxalenye, exhomekeke kwimilinganiselo yenxalenye.

Inkqubo ye-photochemical metal etching iqala ngokudala uyilo usebenzisa iCAD okanye iAdobe Illustrator.Nangona kunjalo, oku akukuphela kobalo lwekhompyuter olubandakanyekayo.Emva kokugqiba ukuyila, ubukhulu bentsimbi bunqunywe, kunye nenani leenqununu ezinokungena kwiphepha lokunciphisa iindleko zokuvelisa.Ukongeza, ukunyamezelwa kwenxalenye kuxhomekeke kubukhulu becala, nto leyo ephinda ichaphazele ubukhulu bephepha.

Ukulungiswa kwesinyithi

Njengoko kufakwe iasidi, intsimbi kufuneka icocwe kakuhle phambi kokuba icocwe.Iqhekeza ngalinye lesinyithi liyakhuhlwa, licocwe, licocwe kusetyenziswa uxinzelelo lwamanzi kunye ne-solvent ethambileyo.Le nkqubo iyayiphelisa ioli, izinto ezingcolisayo kunye namasuntswana amancinane.Oku kuyimfuneko ukubonelela indawo ecocekileyo ecocekileyo yokusetyenziswa kwefilimu ye-photoresist ukubambelela ngokukhuselekileyo.

Laminating Metal Sheets kunye Photoresistant Films

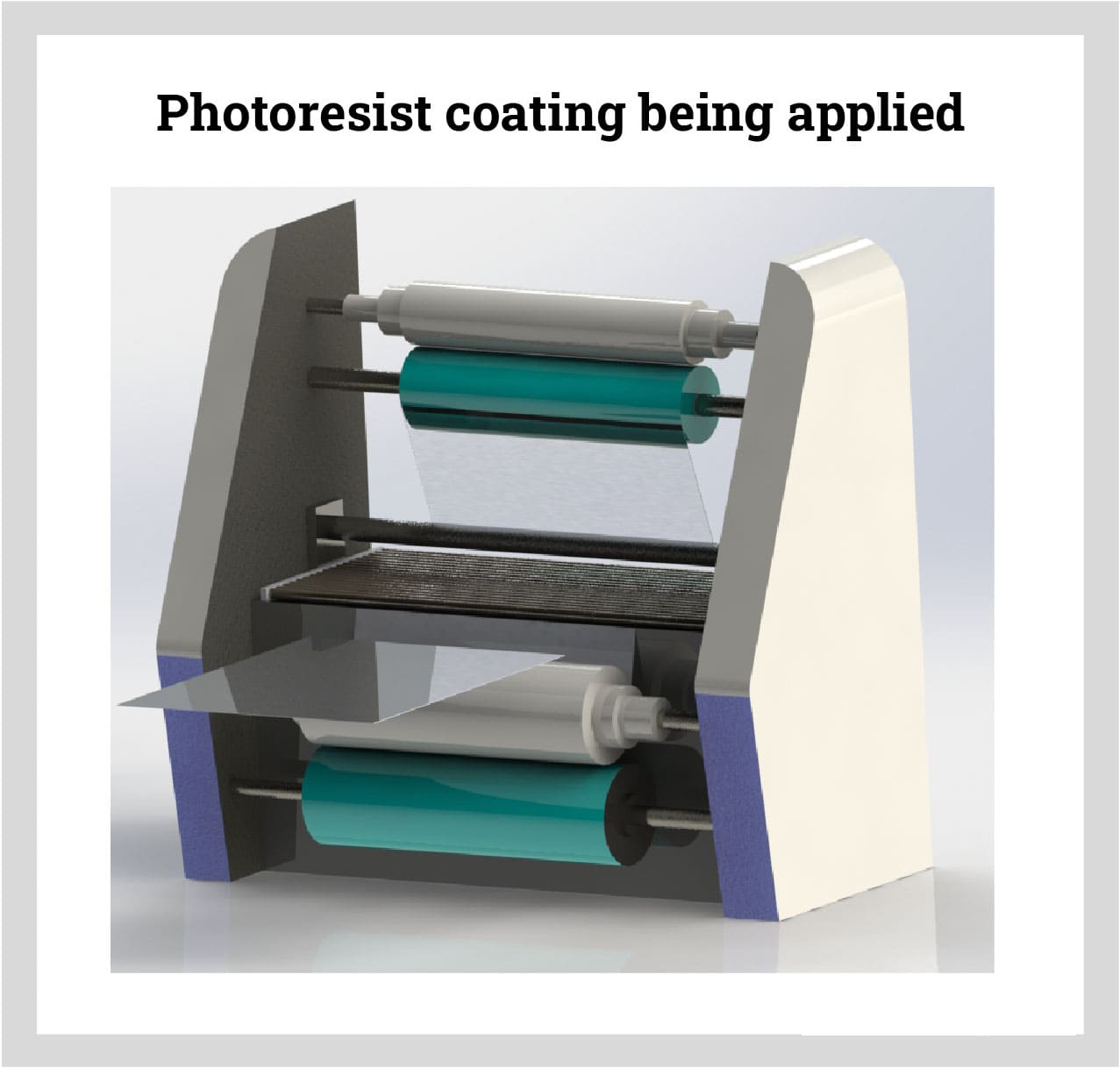

I-Lamination kukusetyenziswa kwefilimu ye-photoresist.Amaphepha esinyithi ahanjiswa phakathi kweerola ezigubungelayo kwaye zisebenzise ngokulinganayo i-lamination.Ukuthintela nakuphi na ukuvezwa ngokungafanelekanga kwamaphepha, inkqubo igqityezelwa kwigumbi elikhanyiswe ngezibane ezityheli ukuthintela ukukhanya kwe-UV.Ukulungelelaniswa okufanelekileyo kwamaphepha kubonelelwa ngemingxuma ebethelwe kwimida yamaphepha.Iibhubhu kwi-coating ye-laminated zithintelwe ngokutywina i-vacuum yokutywina amaphepha, ebeka imigangatho ye-laminate.

Ukulungiselela isinyithi kwi-photochemical metal etching, kufuneka ihlambuluke ngokucokisekileyo ukuze isuse ioli, ukungcola kunye namasuntswana.Isiqwenga ngasinye setsimbi siyahlanjululwa, sicocwe, kwaye sihlanjwe nge-solvent epholileyo kunye noxinzelelo lwamanzi ukuze kuqinisekiswe indawo egudileyo, ecocekileyo yokusetyenziswa kwefilimu ye-photoresist.

Isinyathelo esilandelayo yi-lamination, ebandakanya ukusebenzisa ifilimu ye-photoresist kwiishiti zetsimbi.Amaphepha ahanjiswa phakathi kwee-roller ukuze agqoke ngokulinganayo kwaye asebenzise ifilimu.Inkqubo iqhutyelwa kwigumbi elikhanyayo elityheli ukukhusela ukukhanya kwe-UV.Imingxuma efakwe emacaleni amaxwebhu inika ulungelelwaniso olufanelekileyo, ngelixa ukutywinwa kwe-vacuum kuthoba iileyile ze-laminate kwaye kuthintele amaqamza ukuba enze.

Photoresist Processing

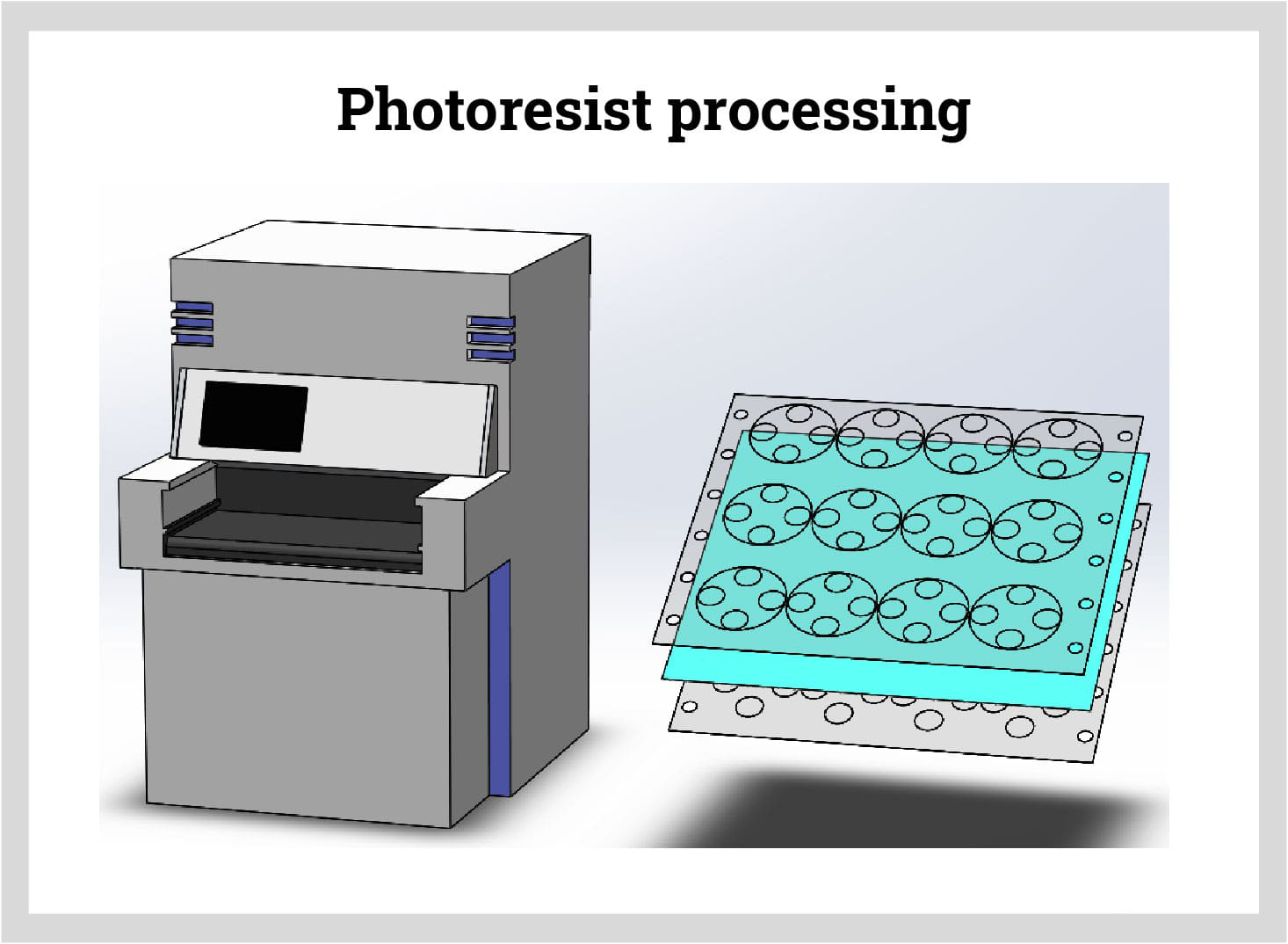

Ngethuba lokucubungula i-photoresist, imifanekiso evela kwi-CAD okanye kwi-Adobe Illustrator yokunikezelwa ibekwe kuluhlu lwe-photoresist kwiphepha lesinyithi.Unikezelo lwe-CAD okanye i-Adobe Illustrator lushicilelwe kumacala omabini ephepha lesinyithi ngokulidibanisa ngaphezulu naphantsi kwentsimbi.Nje ukuba amashiti esinyithi anemifanekiso esetyenzisiweyo, ayavezwa kwisibane se-UV esibeka imifanekiso ngokusisigxina.Apho ukukhanya kwe-UV kukhanya kwiindawo ezicacileyo ze-laminate, i-photoresist iyaqina kwaye iqine.Iindawo ezimnyama ze-laminate zihlala zithambile kwaye zingathinteki ukukhanya kwe-UV.

Kwinqanaba lokucubungula i-photoresist ye-photochemical metal etching, imifanekiso evela kwi-CAD okanye kwi-Adobe Illustrator yoyilo idluliselwe kumaleko we-photoresist kwiphepha lesinyithi.Oku kwenziwa ngokudibanisa uyilo ngaphezulu nangaphantsi kwephepha lesinyithi.Emva kokuba imifanekiso isetyenziswe kwiphepha lesinyithi, ibonakaliswe kukukhanya kwe-UV, okwenza imifanekiso ihlale.

Ngexesha lokuvezwa kwe-UV, iindawo ezicacileyo ze-laminate zivumela ukukhanya kwe-UV ukuba kudlule, kubangela ukuba i-photoresist ibe lukhuni kwaye iqine.Ngokwahlukileyo, iindawo ezimnyama ze-laminate zihlala zithambile kwaye azichatshazelwa kukukhanya kwe-UV.Le nkqubo idala iphethini eya kukhokela inkqubo yokubhala, apho iindawo ezilukhuni ziya kuhlala kwaye iindawo ezithambileyo ziya kufakwa.

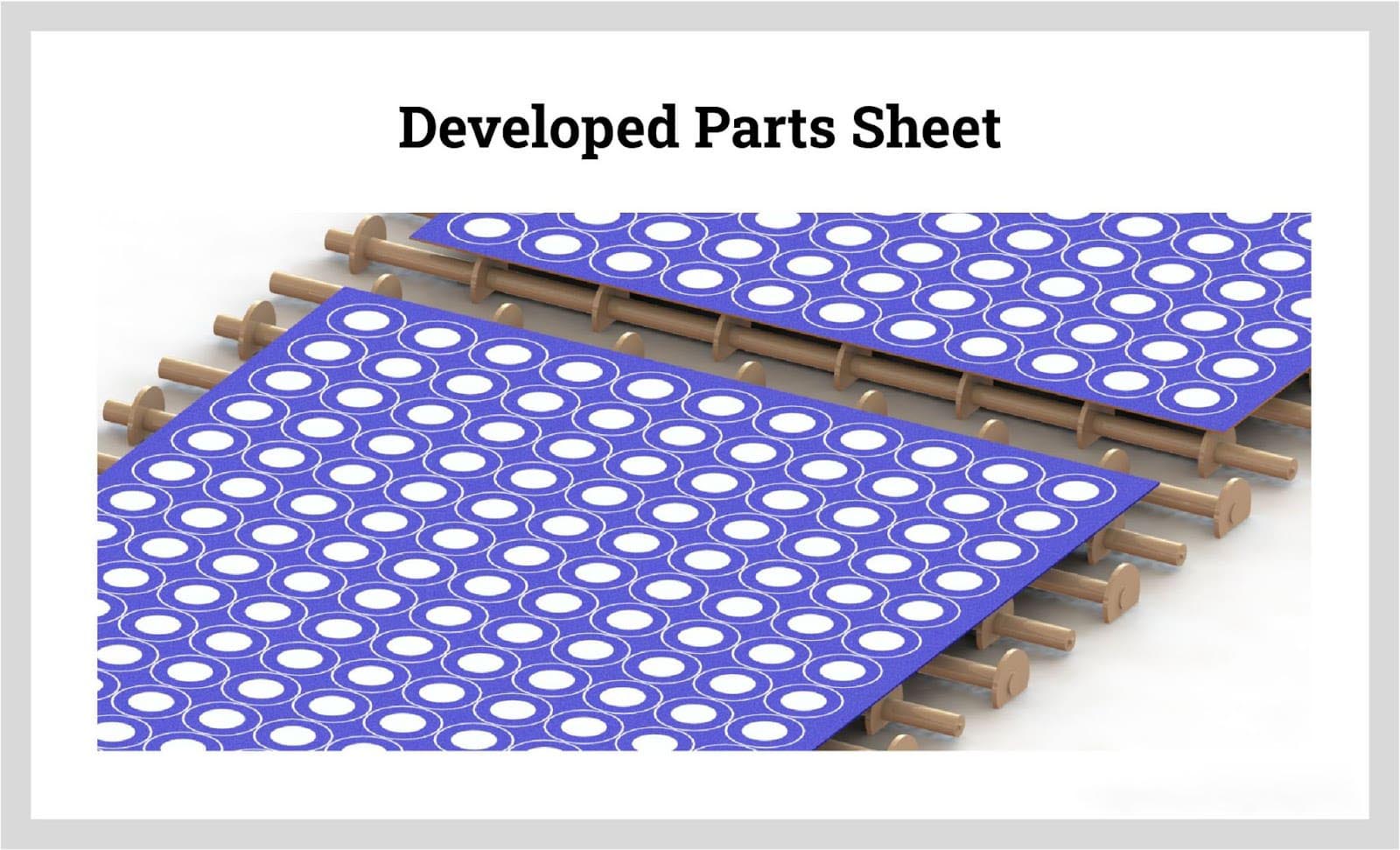

Ukuphuhlisa amaPhepha

Ukusuka kwi-photoresist processing, amashiti afudukela kumatshini ophuhlayo osebenzisa isisombululo sealkali, uninzi lwezisombululo zesodium okanye zepotassium carbonate, ezihlamba ifilimu ethambileyo yefotoresist ishiya iindawo ukuba zifakwe ebhentsisiwe.Inkqubo isusa ukuxhathisa okuthambileyo kwaye ishiya i-resistance eqinile, eyona nxalenye imele ifakwe.Kulo mfanekiso ungezantsi, iindawo ezilukhuni ziluhlaza okwesibhakabhaka, kunye neendawo ezithambileyo ziyigrey.Iindawo ezingakhuselwanga yi-laminate ekhuniweyo zintsimbi eziveziweyo eziza kususwa ngexesha lokudibanisa.

Emva kwesigaba sokucubungula i-photoresist, iishiti zetsimbi zithunyelwa kumatshini ophuhlisayo apho isisombululo se-alkali, ngokuqhelekileyo i-sodium okanye i-potassium carbonate, isetyenziswe.Esi sisombululo sihlamba ifilimu ye-photoresist ethambileyo, ishiya iindawo ezifuna ukufakwa zibonakaliswe.

Ngenxa yoko, ukuchasana okuthambileyo kususwa, ngelixa ukuxhathisa okunzima, okuhambelana neendawo ezifuna ukubethelwa, kushiywe ngasemva.Kwiphethini ephumelayo, iindawo ezilukhuni ziboniswa nge-blue, kunye neendawo ezithambileyo ziyigrey.Iindawo ezingakhuselwanga ngokumelana nokuqina zimela isinyithi esivezwayo esiza kususwa ngexesha lenkqubo yokubhala.

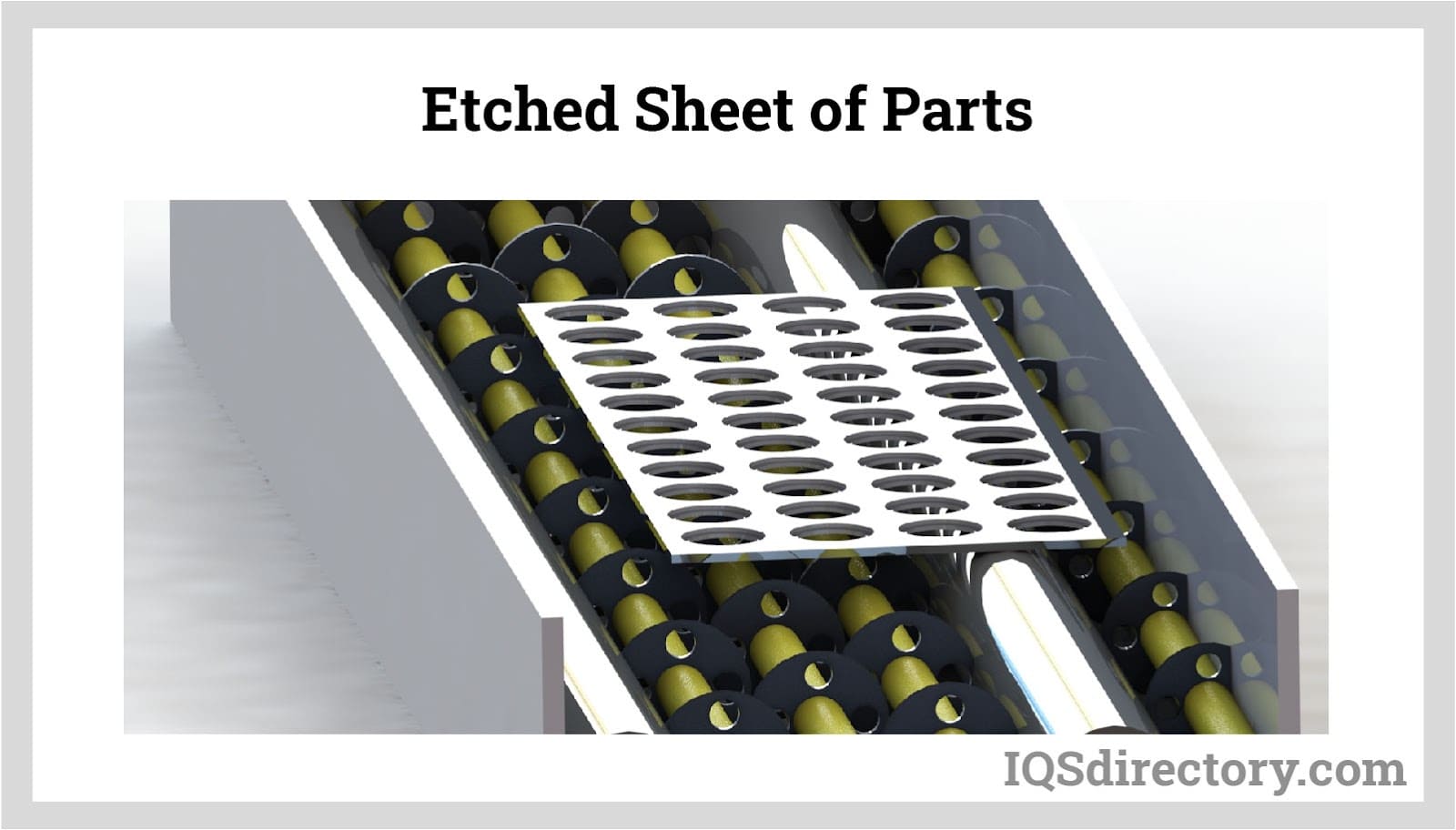

Etching

Ngokufana nenkqubo yokufaka iasidi, amaphepha aphuhlisiweyo abekwe kwi-conveyor ehambisa amaphepha ngomatshini ogalela i-etchant kumaphepha.Apho i-etchant idibanisa nentsimbi eveziweyo, inyibilikisa isinyithi esishiya izinto ezikhuselweyo.

Kwiinkqubo ezininzi ze-photochemical, i-etchant yi-ferric chloride, efafazwa ukusuka ezantsi nangaphezulu kwi-conveyor.I-Ferric chloride ikhethwa njenge-etchant kuba ikhuselekile ukuyisebenzisa kwaye inokuphinda isetyenziswe.I-Cloric chloride isetyenziselwa i-etch copper kunye ne-alloys yayo.

Inkqubo yokufaka i-etching kufuneka ifakwe ngononophelo kwaye ilawulwe ngokuhambelana nentsimbi echongwayo kuba ezinye iintsimbi zithatha ixesha elide ukukhwela kunezinye.Kwimpumelelo ye-photochemical etching, ukujonga ngononophelo kunye nolawulo kubalulekile.

Kwinqanaba le-etching ye-photochemical metal etching, amaphepha esinyithi aphuhlisiwe abekwe kwi-conveyor ebahambisa ngomatshini apho i-etchant igalelwa kumaphepha.I-etchant iyayinyibilikisa intsimbi eveziweyo, ishiya ngasemva iindawo ezikhuselweyo zeshiti.

I-Ferric chloride iqhele ukusetyenziswa njenge-etchant kwiinkqubo ezininzi ze-photochemical ngenxa yokuba ikhuselekile ukuyisebenzisa kwaye inokuphinda isetyenziswe.Ubhedu kunye ne-alloys yayo, i-cupric chloride isetyenziswa endaweni yoko.

Inkqubo yokuhombisa kufuneka ibekwe ngononophelo kwaye ilawulwe ngokohlobo lwentsimbi ekroliweyo, njengoko ezinye iintsimbi zifuna amaxesha amade okuhombisa kunezinye.Ukuqinisekisa impumelelo yenkqubo ye-photochemical etching, ukubeka iliso ngokucophelela kunye nokulawula kubalulekile.

Ukuhluthwa iResist Resist Film

Ngethuba lenkqubo yokuhlutha, i-stripper yokuxhathisa isetyenziswe kwiinqununu ukususa nayiphi na ifilimu eseleyo yokuxhathisa.Emva kokuba ukuhluthwa kugqityiwe, inxalenye egqityiweyo ishiywe, enokubonwa kumfanekiso ongezantsi.

Emva kwenkqubo ye-etching, ifilimu eseleyo yokuxhathisa kwiphepha lesinyithi iyahluthwa ngokufaka i-resistant stripper.Le nkqubo isusa nayiphi na ifilimu yokuxhathisa eseleyo kumphezulu wephepha lesinyithi.

Emva kokuba inkqubo yokuhlutha igqityiwe, inxalenye yentsimbi egqityiweyo ishiywe, enokubonwa kumfanekiso obangelwayo.